תיאור

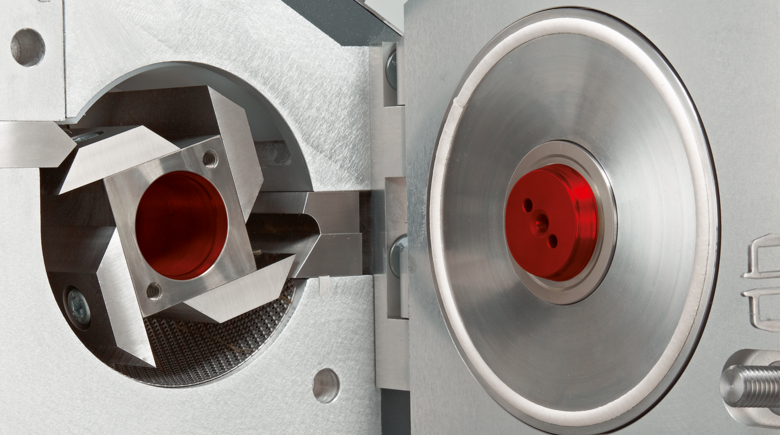

Unique grinding chamber geometry

In Cutting Mills, the sample is comminuted according to the cutting principle of scissors, increasingly fine between the knives of the rotor and fixed knives until the desired final fineness is achieved.

Unique grinding chamber geometry: The grinding chamber is designed with minimal dead space and progressive cutting geometry between rotor and fixed knives. The sample material is continuously moved during comminution and cannot settle anywhere. In conjunctions with the special air flow, this is the basis for swift, blockage-free operation and fast cleaning without residue.

- Fast, reproducible size reduction due to high cutting rotor speed of up to 3400 rpm

- Max. feed size 70 x 70 mm

- Throughput quantity of up to 50 l/h

- Defined final fineness replaceable sieve inserts – 0.25 – 20 mm

- Collecting vessel 3.5 litres or 60 litres

- Funnel for long- and bulk solids or protected funnel made of stainless steel with plastic sample pusher

- Housing and closing lid can be lifted to open completely – lid completely removable

- Externally adjustable cutting gap

- Rotor knives can be turned (2 cutting edges) – double service life

- Very stable: the rotor with double bearing on shaft and in the lid.

- Especially easy FRITSCH cleaning

- Optimum airflow for particularly fast size reduction and secure protection against clogging

- Extensive accessories for simplifying your daily work

Configure your Cutting Mill PULVERISETTE 15 exactly to your specific application

The Cutting Mill PULVERISETTE 15 is delivered without funnel, cutting tool set (consisting of rotors and fixed knives), sieve inserts, collection vessel and stand. Various funnels, collection vessels, rotors with fixed knives, sieve inserts and a support stand enable you to configure the Cutting Mill exactly for your application.

| Working principle | cutting |

| Optimal for material type | medium-hard, soft, fibrous samples |

| Cutting tools | rotor with straight edges and fixed knives |

| Materials of the cutting tools | tool steel, chromium-free tool steel, stainless steel 316L, chromium-free steel DC01 |

| Max. feed size (depending on the material and funnel) | 70 x 70 mm |

| Max. throughput (depending on the material and sieve size) | 50 l/h |

| Final fineness (depends on sieve insert) | 0.25 – 20 mm |

| Feeding | batchwise/continuous |

| Rotor speed (depending on voltage and frequency) | 2,800/3,400 rpm |

| Rotor peripheral speed (depending on voltage and frequency) | 14.9 2 / 17.9 m/s |

| Electrical details* | 400 V/3~, 50 Hz, 1790 Watt |

| Instrument also available in the following voltages | 220-240 V/1~, 50 Hz, 2150 Watt order no. 15.4020.00 |

200 V/3~, 60 Hz, 2140 Watt

order no. 15.4050.00

100-120 V/1~, 60 Hz, 1900 Watt

order no. 15.4010.00Emission sound pressure level at the workplace according to DIN EN ISO 3746 (depending on the material to be ground, rotor and sieve insert used)approx. LpAd = 78 dBWeight32 kgDimensions (W x D x H)table mounted or on support frame 42 x 48 x 69 cm

*The three-phase AC version„/3~“ is definitely preferable over a single-phase version „/1~“, since you obtain with the three-phase AC version more power, better effectiveness and a greater energy efficiency. Please note: the three-phase AC version „/3~“ must always be operated on a three-phase supply network.